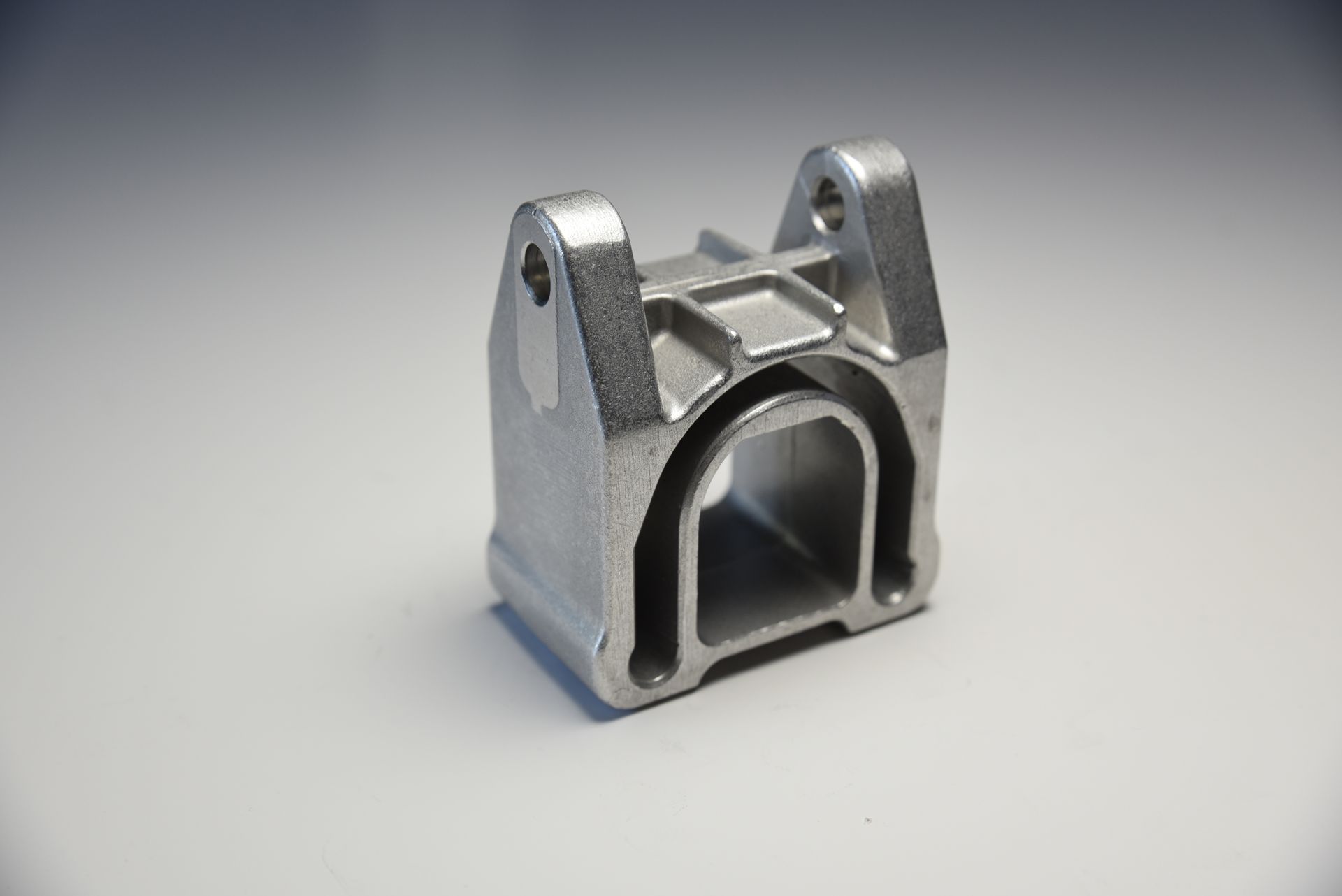

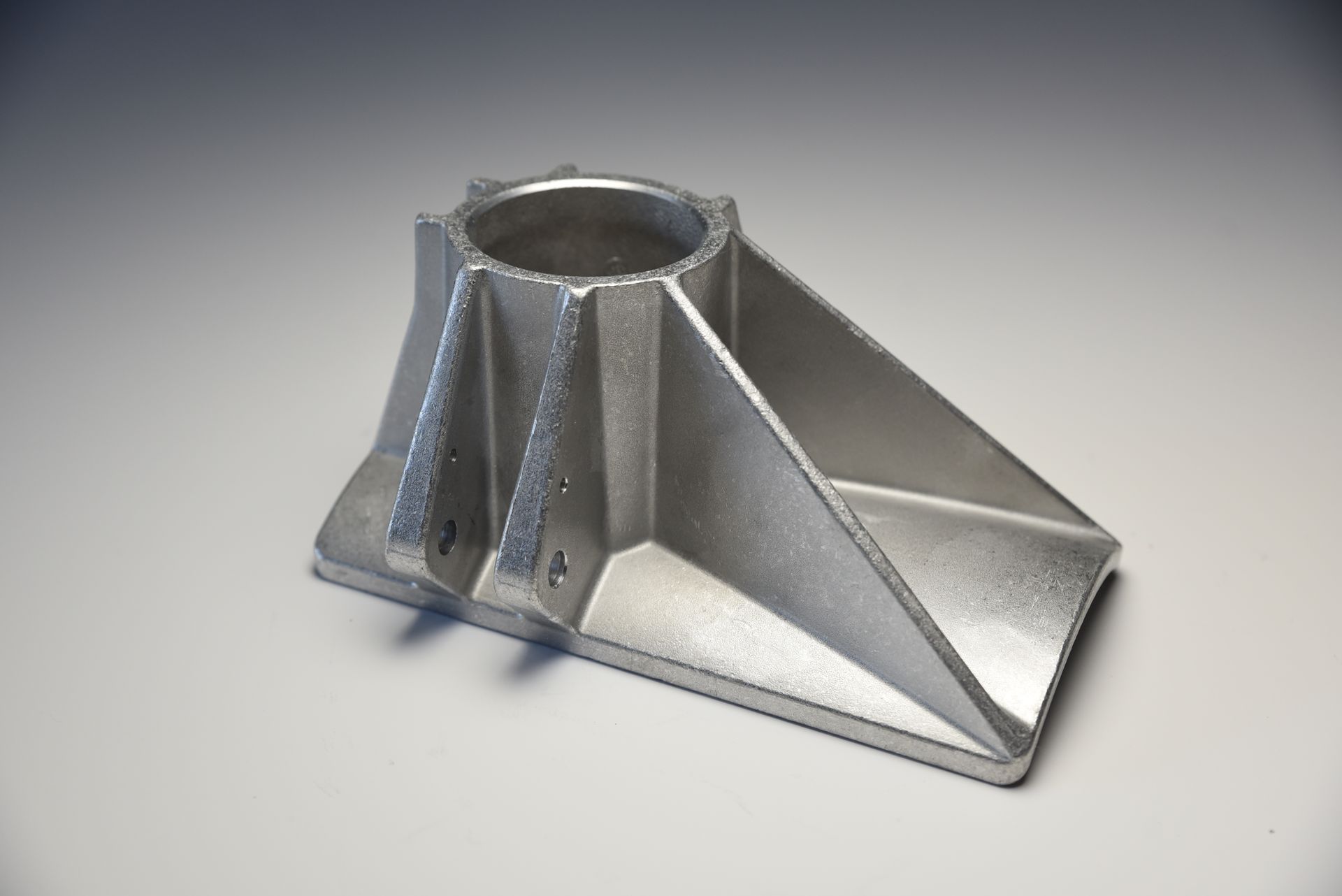

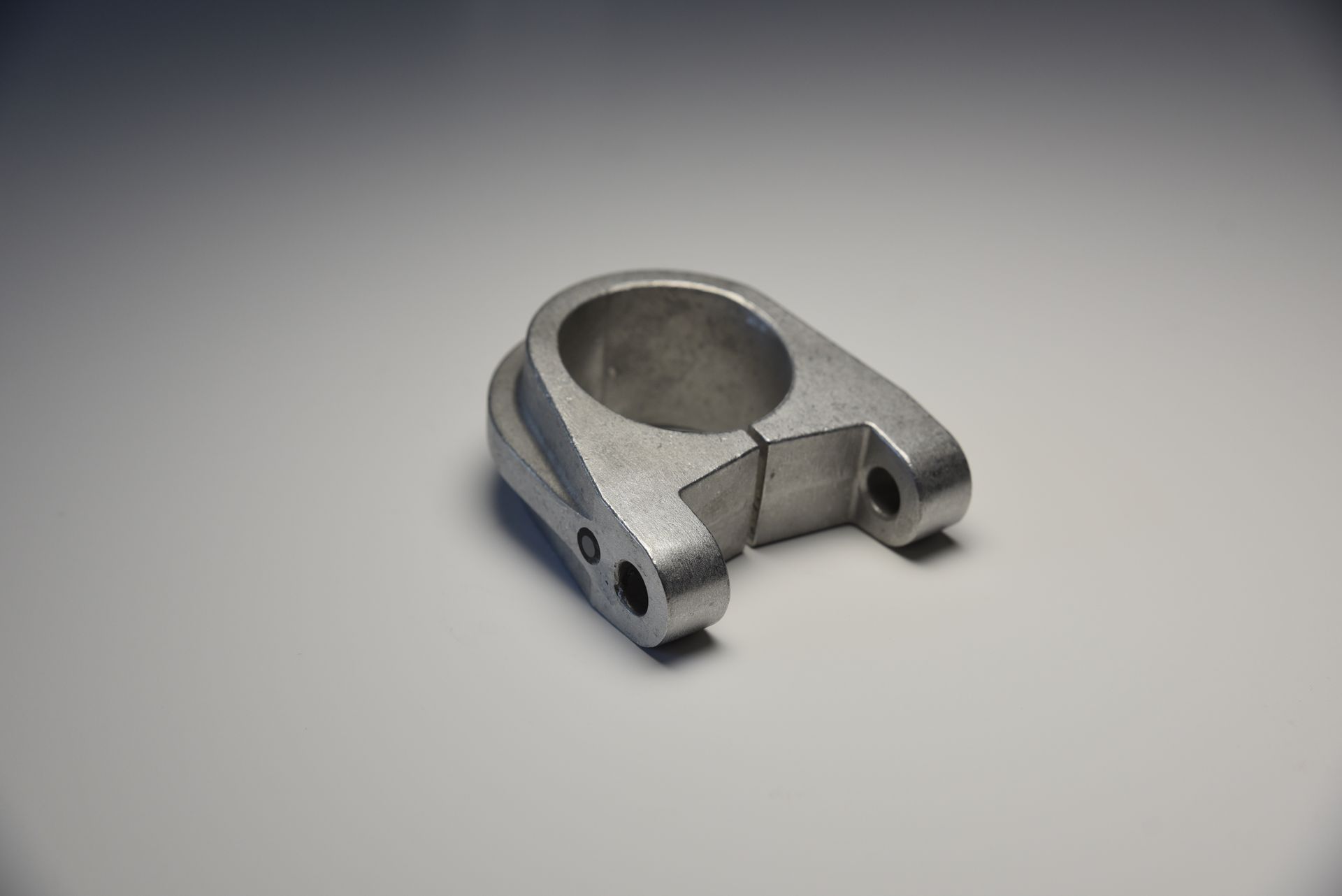

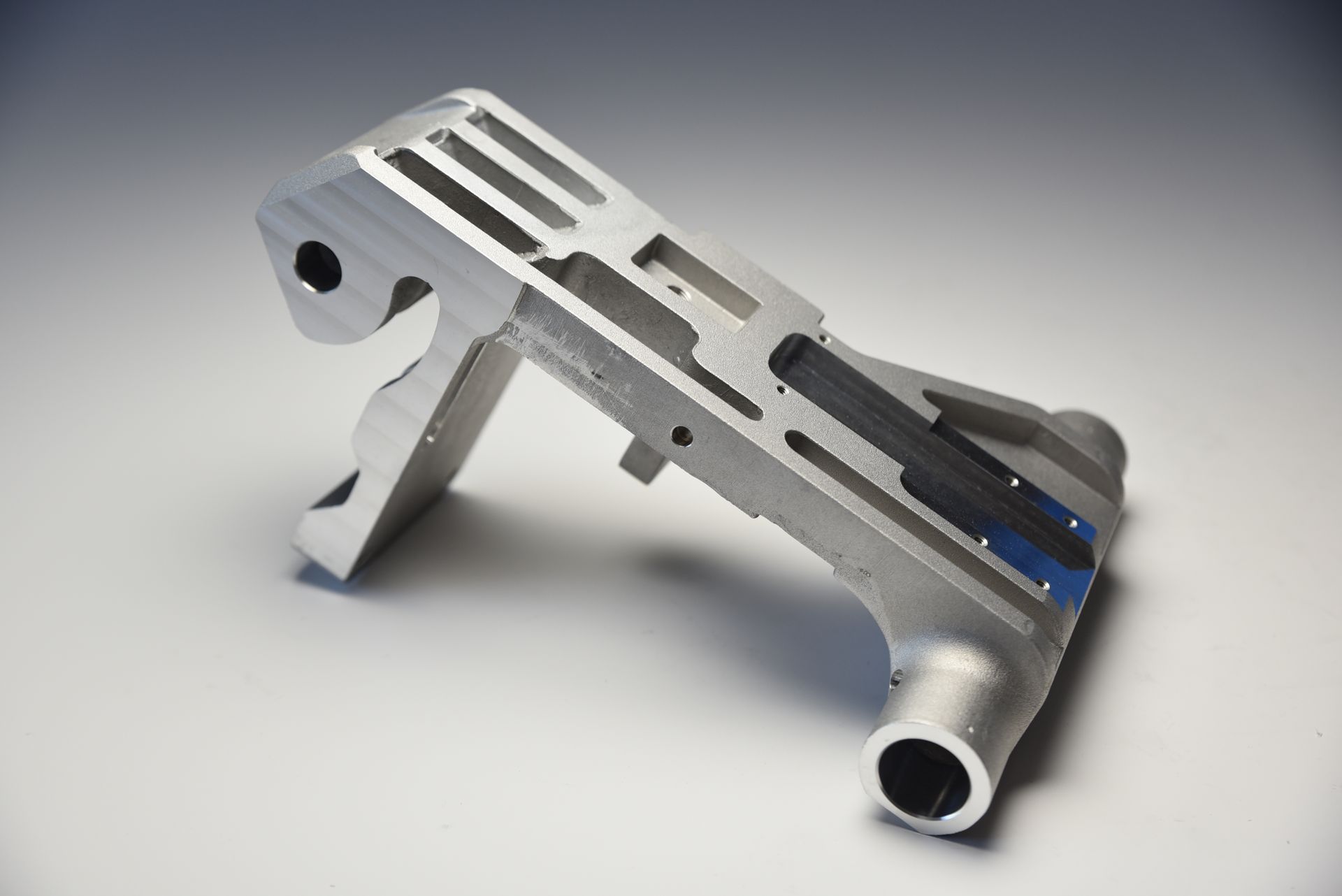

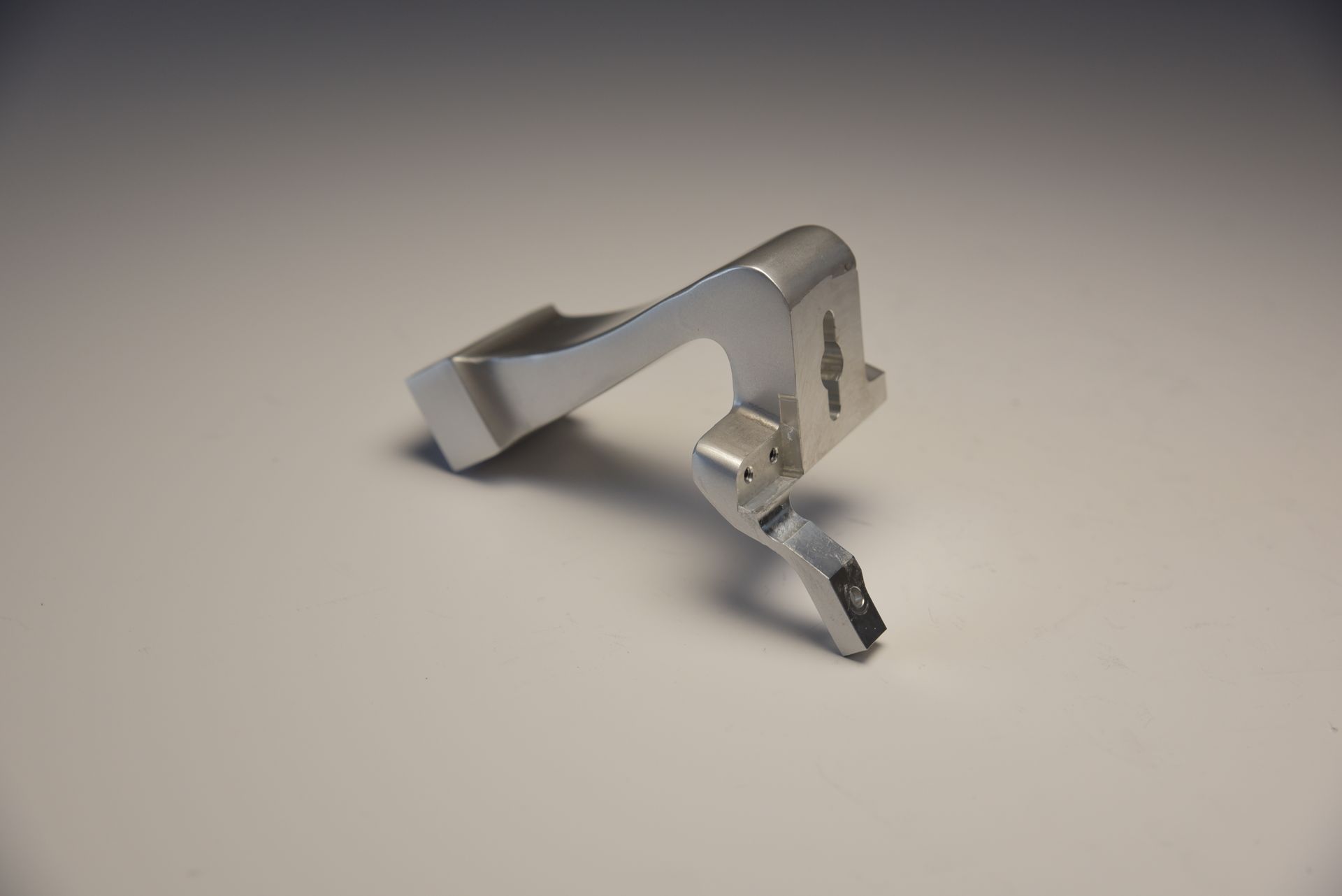

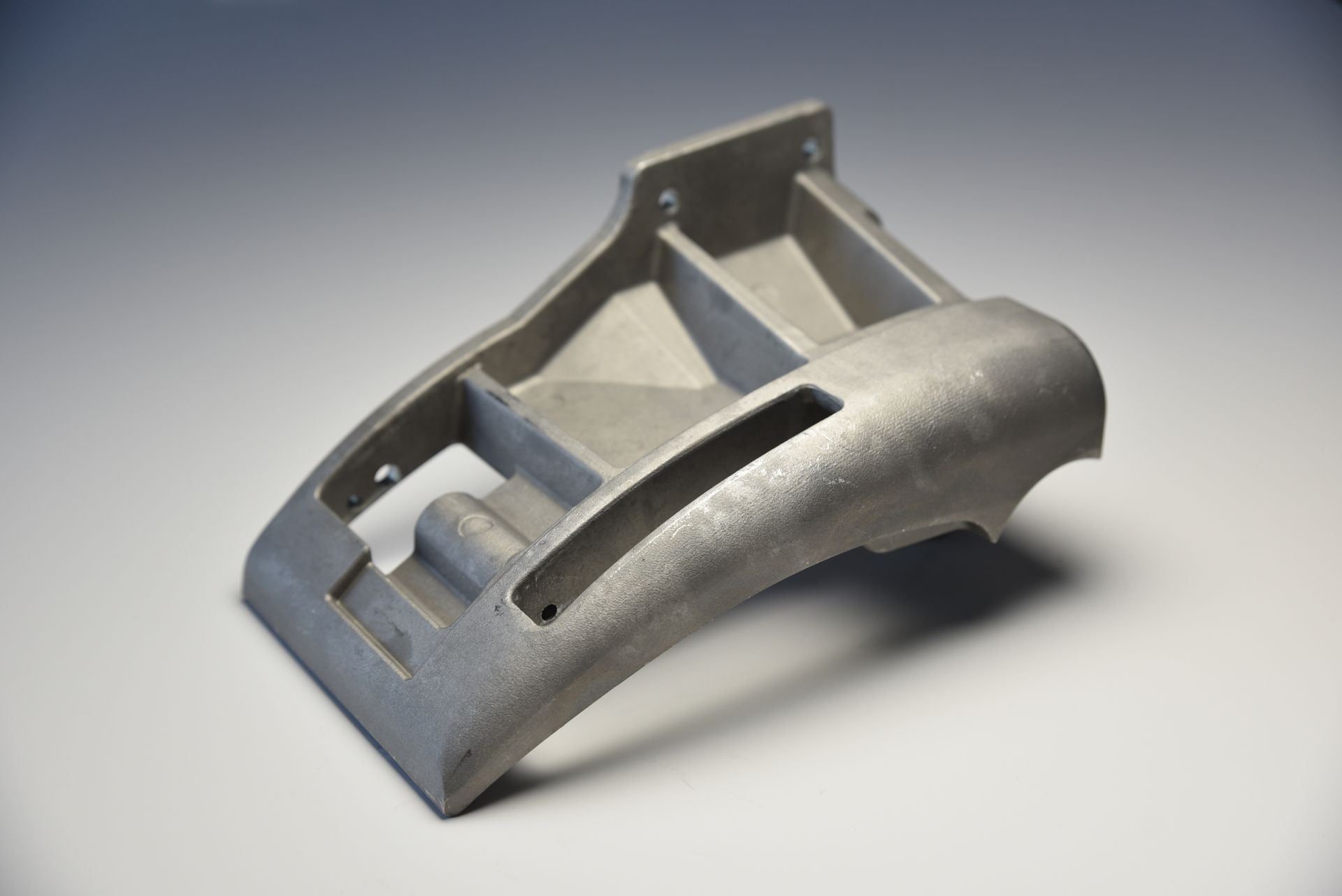

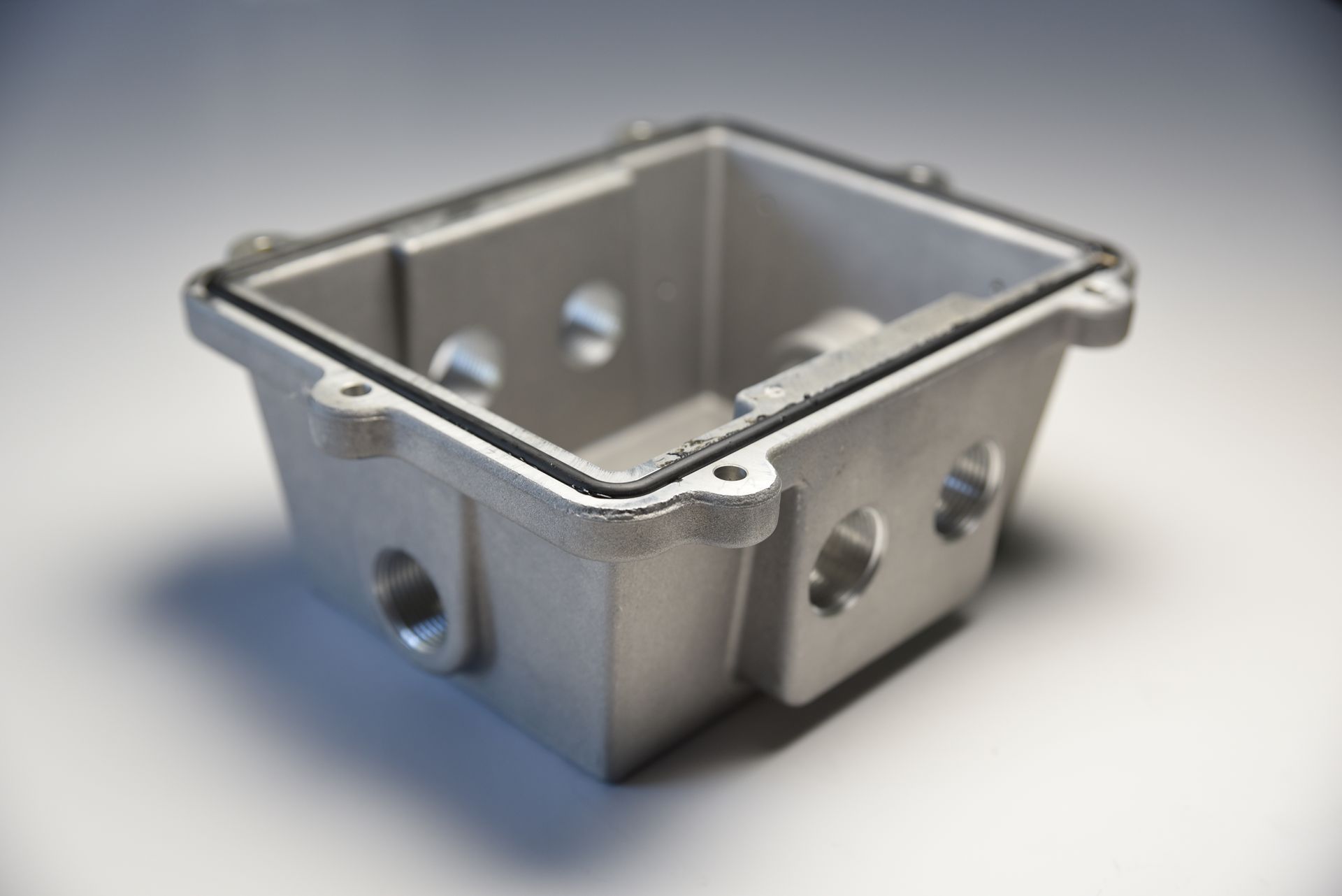

Permanent Mold Casting

Permanent mold casting is a well-established metal casting technique that utilizes reusable molds to create various metal components with precision and efficiency. This method involves the careful process of pouring molten metal into a specially designed mold, where it is allowed to cool and solidify over time. Once the metal has adequately cooled and taken the shape of the mold, the casting is then skillfully extracted from the mold, yielding a finished product that can meet the specific requirements of different applications. This technique is particularly valued for its ability to produce parts with excellent dimensional accuracy and surface finish, making it a popular choice in industries ranging from automotive to machinery manufacturing.

Materials include:

Aluminum

Copper

Part size range:

1.5 Ounces to over 400 Pounds