It’s one thing to have good ideas, but developing them so that they can be transformed into marketable products is something completely different.

Designing a good product prototype is one of the most important steps in developing your product ideas.

Designing a prototype involves:

-

- Developing a digital model

- Developing a physical model

Additionally, we also look at other common questions with prototype design like

product prototype testing

,

companies that build prototypes, how much it costs to make a prototype

,

and how to get the best results in a simple, straightforward and affordable manner.

Sketches and Prototypes

We need to emphasize the difference between simple

sketches and prototypes

. First of all, sketches are non-commital, tentative, and evocative. Prototypes, on the other hand, are used to answer quite specific questions such as: how will this product work?

What functions does it have? What is the mechanism involved?

Moreover, they are quite refined and didactic- used to educate potential business investors about the benefits of your product/idea.

There are high-fidelity and low-fidelity prototypes. The former are quite sophisticated and nowadays involve computer simulation that allows interaction with the product. The latter concern the early stages of developing a prototype, which often involves paper versions that don’t allow substantial interaction with users.

Why Do We Need It?

Before diving into

how to make a product prototype

,

let us look at why it is important to build a prototype in the first place. Firstly, a good, working model increases the chances of you getting the patent, though submitting one isn’t mandatory.

Additionally, it can be a great way to explain your concept/product visually and is a live example that your invention actually works. Thus, a good

product prototype example

can be a great tool to promote your product.

Apple, for instance, paid close attention to prototyping from the very beginning. In 1987, the company started using

translucent prototypes

in order to test the airflow and other performances.

How to Make a Product Prototype

Making a product prototype involves exactly three steps – making a sketch, making a virtual model, and finally making a physical model.

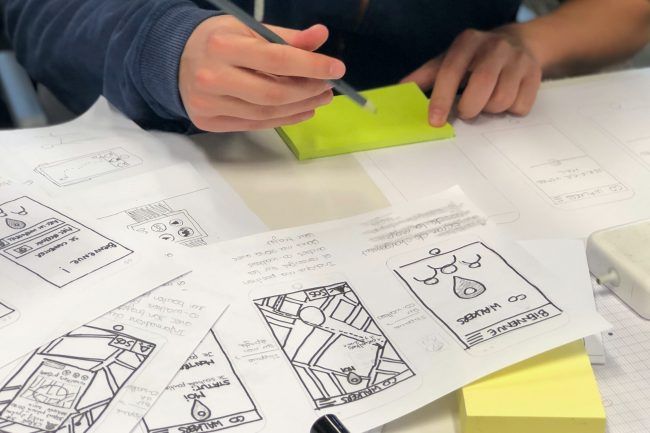

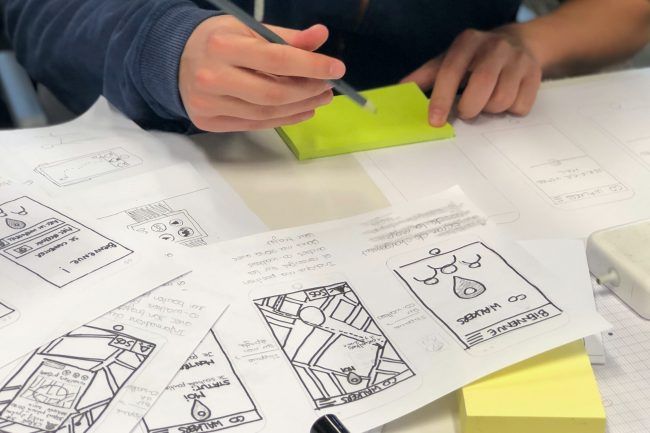

1. Developing the Concept on Paper

The first step of the

product prototype design

is getting the idea onto a sheet of paper. Generally, this involves sketching your ideas and the various parts that make up your product.

Putting down your ideas in writing, sketches, or diagrams not only helps you with the ideation phase, but it can also help you streamline your thoughts and come to a final product faster.

Experts also suggest you put down your ideas in a dedicated notebook, all in the same place, as it serves as documentation in case you have to defend your invention/patent in court.

Finally, as the adage goes, a picture is worth a thousand words

, and a good sketch can make explaining and introducing your product idea to financiers, patenting officials,

companies that build prototypes

or other entities a lot easier.

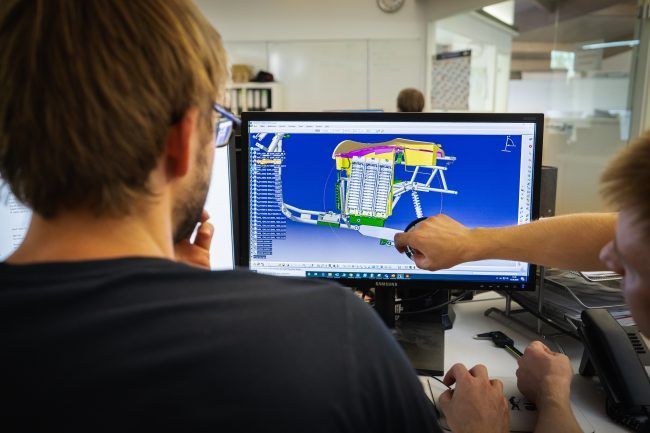

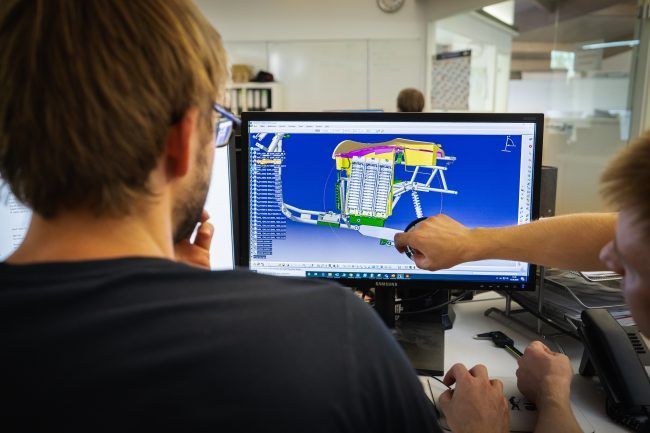

2. Developing a Digital Model

Once everything is in black and white, and once you finally have zeroed it on the product design, the next step is to make a digital prototype

. So, why do we need one? A virtual model makes it easier to visualize the product; there is even

product prototype software

that makes it possible to visualize your model in 3-D. Finally, a good digital model helps in easy digital

product prototype testing

.

So, obviously, the next challenge is

how to make a virtual prototype

. One of the easiest ways to design a digital model is to use

AutoCAD

, which is a commonly used digital tool by designers, architects, and manufacturers all across the world. This tool has been around for decades now and makes creating 2-D and 3-D renderings easy.

There are other digital product prototype software tools

:

Conversely, since not every one of us is as tech-savvy, the best alternative is to opt for the services for a professional prototype designer, like

Mark One Manufacturing

.

A good designer not only removes the initial guesswork involved in mastering a new tool like AutoCAD but approaching an experienced designer also ensures that your digital model is designed to impress. Not to mention their access to industry-leading software that rivals consumer modeling programs in detail and accuracy.

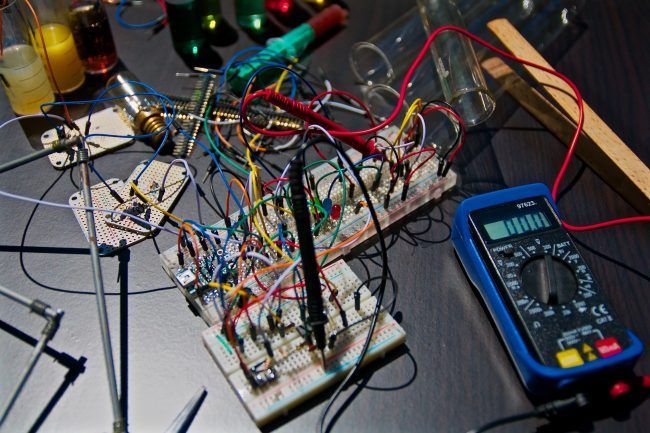

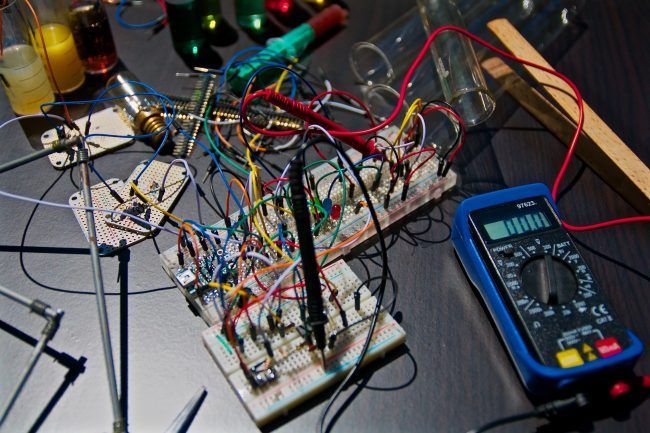

3. Developing a Physical Model

The last and final step in building a product prototype is making a physical model. If you are someone with good DIY skills, building a model from scratch would be relatively easy. In fact, creating an actual working model

might be the most exhilarating and fulfilling step of the whole procedure.

You can start building a working model any way you like; we frequently see many people online and on social media create machines and models from scrap material,

plastic

, and other

recycled material

.

So, what about people who aren’t good at building a physical model? That is when you need to approach an experienced and accomplished professional.

Advantages of Approaching a Professional

Approaching a professional designer is a logical step if you’re not an engineer or a technician. In fact, even if you are confident about your skills, working with a professional can be advantageous in many ways

:

-

- They are knowledgeable and experienced. Since they work with developers and inventors regularly, they can offer great advice on how to design the model efficiently and affordably, what materials to use, and a quote on precise manufacturing materials after the prototype is created.

- The process becomes a lot easier and hassle-free as they already have the required tools.

- Having a professional designer on-board from the beginning makes for a hassle-free transition from designing a prototype to designing the actual product!

How Much Does It Cost to Make a Prototype?

In this section, we’ll focus on high-fidelity prototypes, as they usually necessitate significant investments in terms of time and money.

Let’s say that you want to design a watch, like

Ross Davis

. He doesn’t have the designing and engineering skills, but Ross quickly found an expert via the Internet – and this is also something you can do with the help of numerous freelance platforms like Upwork or Freelancer. After a few days of hard work, Ross had 3D images of the watch he wanted to build, which cost him somewhere around 500-1000$.

Finding a supplier for prototypes was the next step. Ross chose a supplier from Alibaba, but there are also other options like finding a local supplier. Making a good deal with the supplying factory is an art on its own. Ross had to consider numerous factories, ask hundreds of questions, and stay true to his vision.

If you choose the Ross way, always be careful about the minimum order quantity

(MOQ). Factories that bring up dangerously low MOQs (like 50) are likely to cut corners and use cheap materials to reduce their costs. For a factory, making such a small quantity of products will rarely be profitable.

Let Mark One Manufacturing Take Care of It for You

The easiest answer to how to make a product prototype in the most straightforward and hassle-free manner is to let professionals take care of it for you.

Mark One Launch

is an engineering and manufacturing team that specializes in providing customers with convenient, affordable solutions for all their designing and manufacturing requirements. All you have to do is just come to us with your idea! We protect your design with full privacy and offer a wide range of modeling types with the help of our industry professionals in engineering and design.

We have the capability, the resources, and the experience to help you with every stage of your project, right from ideation to manufacturing, marketing, and delivery phases. We are with you right from creating a working model to delivering the finished product. Rooting for you and your product to succeed!

Contact us

or check out our website for more information on

product design, creation, and manufacture

or for any other queries like creating a product prototype.